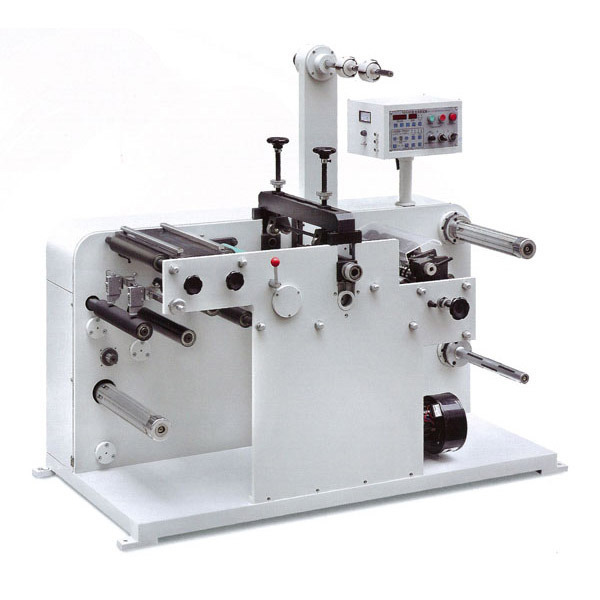

Flexo printing machine

Key words: Machine

DETAILS

1. Adopt the ceramic anilox cylinder to transfer the ink.

2. Unwinding and rewinding are controlled by magnetic power brake and clutch.

3. Each printing unit adopts 360° plate-adjustment.

4. Each printing unit equipped with IR dryer.(UV dryer is for option)

5. This machine with one die-cutting station can make printing and die cutting finished in one process.

6. The ink rollers will be separated from the printing roller, and keep running when the machine stopped.

7. Main motor uses inverter to adjust stepless speed.

8. The machine can finish material-feeding, printing, lighting, drying, laminating, die-cutting and rewinding in a lump. It is an ideal machine for printing adhesive labels.

Flexo printing machine detail :

|

Printing speed |

60m/min |

|

Printing color |

6colours |

|

Max. web width |

320mm |

|

Max. printing width |

310mm |

|

Max. unwinding diameter |

600mm |

|

Max. rewinding diameter |

600mm |

|

Printing length |

177.8-355.6mm |

|

Precision of chromatography |

0.1mm |

|

machine dimensions |

2m x 1.1m x 2.6m |

|

Machine weight |

About 2500kg |

Related products

Welcome to leave a message for consultation