Stripping Machine/paper drilling machine

Key words: Machine

DETAILS

The product is a preferable choice for stripping process after die cutting, such as tags, labels, paper cups, medicine packages, wine packages, cosmetic packages and so on. It saves labor, improve the product quality, and increase the production efficiency.

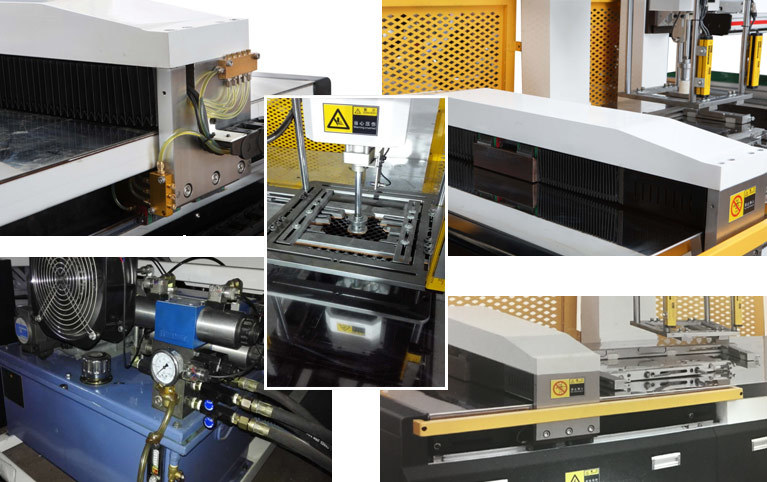

1. Centralized lubrication system

2. Paper gauge with hidden motor and ball screw

3. Adjustable hydraulic system

4. Safety fence

More detail :

1. Compraring to traditional stripping machine which uses gantry frame as the base for installing the stripping mould, our new design adopts one-side independent standing base for installing the stripping mould; this design is space saving, and convinient for operating.

2. Hidden type servo motor and ball screw ensures a precise pile positioning.

3. Adjustable hydraulic system provides adjustable pressure for processing of different materials of different sizes and weights.

4. Stripping needles (rods) are quick and easy to chang to fit differnent products fromats and patterns.

5. Rotatable upper mould can rotate up to 180 degrees to fit products of irregular and unevern patterns. (T)

6. Automatci lubricating system carries out regular lubrication, which greatlty extend the service life of the machine.

7. The operation panel adopts visual button to avoid safety accident caused by wrong operation. Its also easy and quick to program at the touch screen.

8. Safety fence at operation side protects the safety of personnel when the machine is running.

Machine parameter :

|

Model |

HTQF-680 |

HTQF-920 |

HTQF-1080 |

|

Max sheet size (X) mm |

680 |

920 |

1080 |

|

Max sheet size (Z) mm |

460 |

680 |

780 |

|

Min sheet size (X) mm |

400 |

550 |

650 |

|

Min sheet size (Z) mm |

300 |

400 |

450 |

|

Max pile height mm |

100 |

100 |

100 |

|

Min pile height mm |

40 |

40 |

40 |

|

Work table height mm |

850 |

850 |

850 |

|

Max product size to be punched out |

230*230 |

320*320 |

360*360 |

|

Min. product size to be punched out |

30*30 |

30*30 |

30*30 |

|

Stripping speed times/min |

15-22 |

15-22 |

15-22 |

|

Max. force (bar) |

70 |

70 |

70 |

|

Machine installation data |

|||

|

Model |

HTQF-680 |

HTQF-920 |

HTQF-1080 |

|

Machine width mm |

1910 |

2400 |

2760 |

|

Machine depth mm |

1480 |

1800 |

2070 |

|

Machine height mm |

1940 |

1940 |

1960 |

|

Net weight kg |

1200 |

1600 |

2000 |

|

Air source Bar |

4-7 |

4-7 |

4-7 |

|

Air consumption L/min |

2 |

2 |

2 |

|

Power supply voltage |

360V-420V,50/60HZ |

360V-420V,50/60HZ |

360V-420V,50/60HZ |

|

Power consumption A |

2 |

2 |

2 |

|

Insurance current A |

10 |

10 |

10 |

|

Input power |

3hPE |

3hPE |

3hPE |

|

Rotating mould technical parameters |

||

|

Model |

HTT-920 |

HTT-1080 |

|

Trip |

0-180 degrees |

0-180 degrees |

|

Rotating speed |

10-80 degree/second |

10-80 degree/second |

|

Air consumption |

1 L/min |

1 L/min |

|

Air source |

4-7 bar |

4-7 bar |

|

Power supply voltage |

220V, 50HZ |

220V, 50HZ |

|

Power consumption |

0.75KW |

0.75KW |

|

Manipulator arm technical parameters |

|||

|

Model |

HTR-1200 (for 680) |

HTR-1300 (for 920) |

HTR-1400 (for 1400) |

|

Trip |

1200 mm |

1300 mm |

1400 mm |

|

Clamping weight |

50-1000 g |

50-1200 g |

50 -1500 g |

|

Empty running speed |

5-50 m/minute |

5-50 m/minute |

5-50 m/minute |

|

Air source |

4-7 bar |

4-7 bar |

4-7 bar |

|

Air consumption |

1 L/min |

1 L/min |

1 L/min |

|

Power supply voltage |

220V, 50HZ |

220V, 50HZ |

220V, 50HZ |

|

Power consumption |

0.4KW |

0.4KW |

0.4KW |

|

Net weight |

150 kg |

180 kg |

200 kg |

INQUIRY

Related products

Welcome to leave a message for consultation